Dr Series Gas Dryer

APLICACIONES

Use in sensors, semiconductor manufacturing, film and packaging material licenses, powder material transportation, spraying systems, food industry, pharmaceutical industry, etc. require distributed air sources with low dew point of -80℃ dry and clean.

Características del producto

Parámetros del producto

| Modo | DR-300 | DR-600 | DR-1200 |

| Pressure range | 0.65~1.0Mpa | ||

| Dew point temperature | -70℃ | ||

| Gas processing capacity | 425L/Min | 900L/Min | 1750L/Min |

| Finished gas volume | 300L/Min | 600L/Min | 1200L/Min |

| Tamaño de la conexión | ZG1/2 | ZG1/2 | ZG3/4 |

| Potencia | 220V 15W | ||

| Dimensión cm | 200*180*1250 | 450*180*1250 | 450*180*1250 |

Distributed gas sources used in sensors, semiconductor manufacturing, film and packaging material licensing, powder material transportation, spraying systems, food industry, pharmaceutical industry, etc. that require -80℃ low dew point drying and cleaning.

Additional filtration of oil and particulate matter, with airflow passing through a filtration level of 0.01 μm, the pre filter prevents the desiccant from being contaminated by dust and oil (which greatly shortens the lifespan of the desiccant).

The compressed air dryer consists of multiple sets of filter cartridges filled with desiccants. The compressed air in the form of mist alternately flows through multiple sets of filter elements, and the moisture in the air will accumulate on the surface of the dryer. After the filtration process reaches a predetermined duration, the airflow will switch to other filter elements, and a portion of the airflow (discharge airflow) will be used to regenerate the dryer of the first filter element. The flushing airflow will be released into the atmosphere. The service life of desiccants is approximately 15000 working hours.

Product Advantages

- Resultados de estabilidad y repetibilidad de la producción eficientes;

- Utilización de intercambiadores de calor de placas y calentadores de tuberías para mejorar los índices de refrigeración y calefacción;

- Rango de temperatura muy amplio, sin necesidad de sustituir el medio líquido;

- Sistema totalmente cerrado que prolonga la vida útil de los líquidos conductores térmicos;

- Adoptando la bomba de accionamiento magnético, no hay problema de fugas del sello del eje;

- Tecnología de refrigeración de alta temperatura, directamente iniciar el compresor para enfriar a 300 ℃.

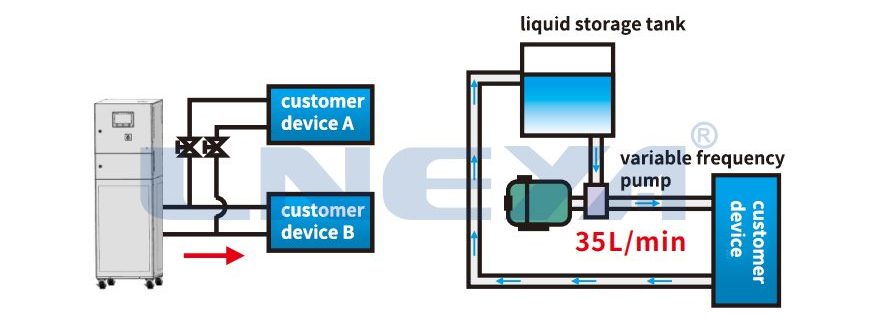

La bomba de frecuencia variable puede ajustar la presión hidráulica de circulación y el caudal

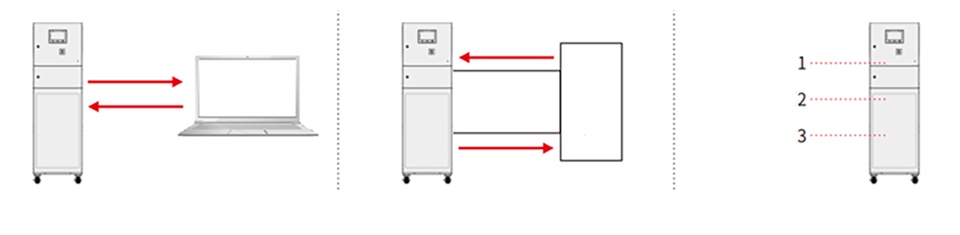

client output signal

Communication function

APLICACIONES

Such as chillers that control the processing temperature on the Fab equipments.

Cooling of CMOS/CCD sensors in semiconductor metrology systems.

Recirculating Chiller for semiconductor metering AOI system.

Refrigerador de un canal refrigerado por aire, diseñado principalmente para máquinas de grabado. Se utiliza para proporcionar un control independiente de la temperatura de las paredes laterales de la cámara.

Used for plasma bevel etch and deposition; Thermal Atomic Layer Etching of Metal Tungsten.

LNEYA provides customized Chiller services

custom chiller sizes

Whether it is portable, compact, large and small chillers, we can custom design them according to your requirements. No matter how many tons of chiller you need, we can create the best solution.

custom chiller types

We provide chillers of various refrigeration types, including but not limited to air-cooled, water-cooled and evaporative-condensing chillers. Regardless of the type of refrigeration compressor, we can design it according to your requirements.

custom temperature ranges

We can create a custom solution for temperatures from -150℃ to +350℃. Custom temperature ranges for specific industries.

custom chiller voltage

Customize chiller voltage and phase according to your needs. Optional 110V/60HZ, 220V/60HZ, 380V/50HZ, 220V/50HZ, 400V/50HZ, 460V/60HZ, 440V~480V/60HZ, etc.

Visite la fábrica de LNEYA

¿Por qué elegir lneya como proveedor de control de temperatura?

Años de experiencia

Clientes satisfechos

m² Área de producción

Tecnologías patentadas

Contacto

Envíenos su solicitud y nos pondremos en contacto con usted en 24 horas

LNEYA Enfriadoras industriales Fabricante Proveedor

LNEYA Enfriadoras industriales Fabricante Proveedor